Product Details

The Tru-Flow® Splitter System is designed to outlast traditional concrete distribution boxes due to its sturdy, non-corrodible polypropylene frame. This innovative splitter system will evenly split effluent into between two and five lines.

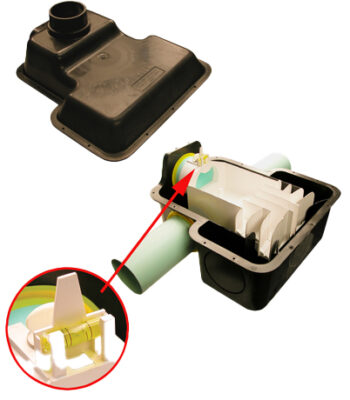

The system is made of two key parts: (1) the diverter basin & cover (2) the adjustable diverter.

The Tru-Flow® unit can tolerate settlement of as much as 15º front-to-back (30º total) and/or 12º side-to-side (24º total). Even with the box out of level, the unit will evenly split effluent when the diverter is adjusted properly. With the inclusion of a small 4″ or 6″ diameter riser flush-to-grade, you can level the Tru-Flo Splitter even after it has been buried and settled. So, you can be certain that all lateral lines are always receiving equal flow. This is a significant advancement over traditional distribution boxes. When traditional boxes are buried and eventually settle, there is no way to ensure all lines were receiving equal flow.

The Splitter System works with all gravity flows and can receive pumped effluent up to 30 gpm. This unique design has no parts to wear out and utilizes non-corrodible materials.

;)

;)