Product Details

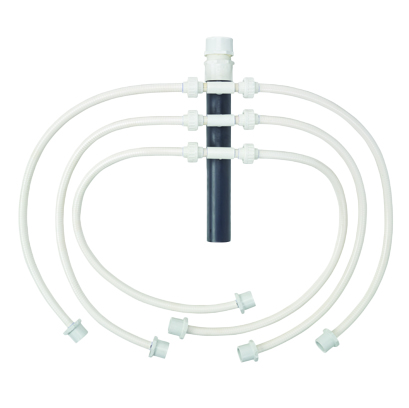

Our Spider Valve® assembly is designed to equally split septic effluent under pump pressure into six lateral lines. It is ideal for septic system applications with six lateral lines of unequal length. This often occurs with a home built on a small lot or when a replacement drain field is required. In such instances, a traditional distribution box is unable to split flow proportionally to lateral lines of unequal length. If that is the case, the Spider Valve is the answer.

Six lateral lines receive flow from the spider valve and then flow by gravity within the lines. Orifices within the manifold can be drilled to allow equal flow to each line. The six lateral Spider Valve assembly includes 5/32” predrilled washers and a union for each washer. Unions allow washers to be removed for cleaning and maintenance. A spider valve sizing program is available to calculate orifice size so that equal flow is obtained per line.

;)

;)