Applications For

Homeowners

Applications

Professionals

Applications

Our high-quality sump pumps and backup systems can dependably protect your home and keep you and your family safe and dry.

Learn MorePumps

- Model 53 Sump Pump

- Model 63 Sump Pump

- Model 73 Sump Pump

- Model 75 Sump Pump

- Model 98 Sump Pump

- Model 95 Sump Pump

- Model 137 Sump Pump

- Model 57 Sump Pump

- View All

Systems & Packages

- Aquanot® Key 507

- Aquanot® Spin 508

- Aquanot® Fit 508

- Aquanot® Spin 508 ProPak with M53

- Aquanot® Fit 508 ProPak with M53

- Aquanot® Fit 508 ProPak with M63

- Aquanot® Spin 508 ProPak with M98

- Aquanot® Fit 508 ProPak with M98

- View All

Accessories & Parts

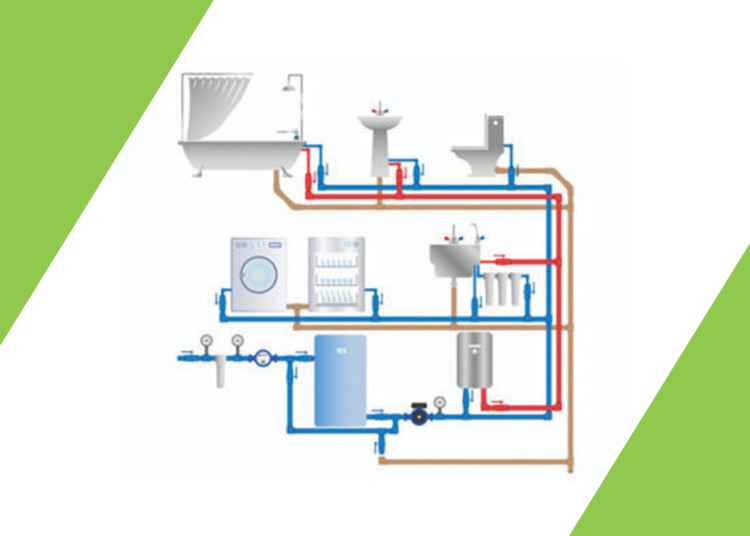

Sewage or grinder pumps move raw sewage and unwanted water away from the home. Our pre-plumbed packages make selecting and installing the right equipment easy.

Learn MorePumps

- Model 264 Sewage Pump

- Model 267 Sewage Pump

- Model 212 Sewage Pump

- Model 818 Grinder Pump

- Model 270 Sewage Pump

- Model 270 Sewage Pump

- Model 803 Grinder Pump

- Model 805 Grinder Pump

- View All

Systems & Packages

- 912 Simplex Sewage Package System with an M264

- 912 Simplex Sewage Package System with an BN264

- 912 Simplex Sewage Package System with an M264

- 912 Simplex Sewage Package System with an M264

- 912 Simplex Sewage Package System with an BN264

- 912 Simplex Sewage Package System with an BN264

- 912 Simplex Sewage Package System with an M266

- 912 Simplex Sewage Package System with an BN266

- View All

Accessories & Parts

- 18″ Riser for Outdoor 24×24 Sewage Ejector System

- 8″ Extension for Indoor 24×24 Sewage Ejector System

- Fiberglass Extension for 18×30 Dia Basin (6″ Tall)

- Fiberglass Extension for 18×30 Basin (12″ Tall)

- PSF Extension for 18×30 Basin (6″ Tall)

- PSF Extension for 18×30 Basin (12″ Tall)

- Standard APak® Outdoor Alarm System With Mechanical Float

- 2″ Tri-Check® Valve

- View All

When sanitary sewers are not available, septic systems are used to treat wastewater before disposal.

Learn MorePumps

- Model 152 Effluent Pump with Switch

- Model 153 Effluent Pump with Switch

- Model 98 Effluent Pump with Switch

- Model 140 Effluent Pump with Switch

- Model 53 Effluent Pump with Switch

- Model 151 Effluent Pump with Switch

- Model 145 Effluent Pump with Switch

- Model 137 Effluent Pump with Switch

- View All

Systems & Packages

- Turbine STEP Vault

- Centrifugal STEP Vault

- Tru-Flow® Splitter System

- Model 6402 Two Outlet Automatic Multizone Valve

- Four Outlet Multizone Valve Assembly

- Six Lateral Spider Valve®

- View All

Accessories & Parts

Crawl spaces get damp, leading to mold and structural damage. Our sumps manage moisture, preventing these issues.

Learn MoreSystems & Packages

Accessories & Parts

Install a sink drain anywhere without breaking concrete. Use our drain pumps for easy installation in areas without gravity drainage.

Learn MorePumps

- Model 2057 Intermittent High Temperature Pump with Switch

- Model 2098 Intermittent High Temperature Pump with Switch

- Model 3098 High Temperature Pump

- Model 2137 Intermittent High Temperature Pump with Switch

- View All

Systems & Packages

- Model 105 Standard Drain Pump

- Model 131 High Flow Drain Pump

- Model 135 High Head and Flow Drain Pump

- View All

Accessories & Parts

Ideal for draining swimming pools, hot tubs, basements, and other areas, our portable dewatering pumps are affordable and easy to transport or store.

Learn MorePumps

Add a full or half bathroom to an area without gravity drainage by using our upflush toilet systems to avoid breaking concrete.

Learn MorePumps

Systems & Packages

- Model 200 Qwik Jon Choice

- Qwik Jon® Choice Ship-To-Home

- Model 201 Qwik Jon Premier

- Qwik Jon® Premier Ship-To-Home

- View All

Accessories & Parts

Remove condensation from air conditioning equipment, condensing furnaces, dehumidifiers, ice makers, water coolers, and refrigeration systems when gravity flow is not an option.

Learn MorePumps

Fountain pumps add a unique focal point and value to your property. The environmentally friendly, water-cooled motor eliminates pollution risk and pond contamination.

Learn MorePumps

Unwanted water and raw sewage are pumped to an outside basin. Sewage lift station pumps take this wastewater up and away.

Learn MorePumps

- Model 282 Sewage Pump

- Model 284 Sewage Pump

- Model 284 Sewage Pump

- Model 292 Sewage Pump

- Model 292 Sewage Pump

- Model 294 Sewage Pump

- Model 293 Sewage Pump

- Model 295 Sewage Pump

- View All

Systems & Packages

- 922 Duplex Prepackaged System with E840

- 922 Simplex Prepackaged System with E820

- 922 Simplex Prepackaged System with Reversing E840

- View All

Accessories & Parts

Effluent lift stations collect and pump the grey water or effluent from commercial facilities or wastewater treatment systems.

Learn MorePumps

- Model 161 Effluent Pump

- Model 163 Effluent Pump

- Model 188 Effluent Pump

- Model 165 Effluent Pump

- Model 191 Effluent Pump

- Model 189 Effluent Pump

- Model 186 Effluent Pump

- View All

Accessories & Parts

Elevator sump pumps prevent environmental contamination before it starts by stopping the pump at the appropriate time with our oil smart system.

Learn MorePumps

Systems & Packages

- Model 940 Oil Guard® System with N153

- Model 940 Oil Guard® System with N153 (SO jacketed cord)

- Model 940 Oil Guard® System with N152

- Model 940 Oil Guard® System with N152 (SO jacketed cord)

- Model 940 Oil Guard® System with N161 (SO jacketed cord)

- Model 940 Oil Guard® System with N161

- View All

Accessories & Parts

During storms, excess water can lead to flooding, pollution, and damage. We offer a range of pumps, containers, and controls to manage your stormwater effectively.

Learn MorePumps

- Model 282 Sewage Pump

- Model 284 Sewage Pump

- Model 292 Sewage Pump

- Model 292 Sewage Pump

- Model 294 Sewage Pump

- Model 293 Sewage Pump

- Model 295 Sewage Pump

- Model 404 Sewage Pump

- View All

Accessories & Parts

- Model 2057 Intermittent High Temperature Pump with Switch

- Model 2098 Intermittent High Temperature Pump with Switch

- Model 3098 High Temperature Pump

- Model 2137 Intermittent High Temperature Pump with Switch

- Model 803 Grinder Pump

- Model 805 Grinder Pump

- Model 807 Grinder Pump

- Model 53 Sump Pump

- Model 63 Sump Pump

- Model 73 Sump Pump

- Model 75 Sump Pump

- Model 98 Sump Pump

- View All

- Aquanot® Key 507

- Aquanot® Spin 508

- Aquanot® Fit 508

- Aquanot® Spin 508 ProPak with M53

- Aquanot® Fit 508 ProPak with M53

- Aquanot® Fit 508 ProPak with M63

- Aquanot® Spin 508 ProPak with M98

- Aquanot® Fit 508 ProPak with M98

- 540 FLEX®Water Powered Backup

- AGM Maintenance Free Battery

- Flooded Maintenance Free Battery

- 922 Duplex Prepackaged System with E840

- View All

- Model 152 Effluent Pump with Switch

- Model 152 Effluent Pump

- Model 98 Effluent Pump

- Model 140 Effluent Pump

- Model 153 Effluent Pump

- Model 153 Effluent Pump with Switch

- Model 98 Effluent Pump with Switch

- Model 140 Effluent Pump with Switch

- Model 53 Effluent Pump

- Model 161 Effluent Pump

- Model 53 Effluent Pump with Switch

- Model 151 Effluent Pump with Switch

- View All

- 18″ Riser for Outdoor 24×24 Sewage Ejector System

- 8″ Extension for Indoor 24×24 Sewage Ejector System

- Fiberglass Extension for 18×30 Dia Basin (6″ Tall)

- Fiberglass Extension for 18×30 Basin (12″ Tall)

- PSF Extension for 18×30 Basin (6″ Tall)

- PSF Extension for 18×30 Basin (12″ Tall)

- AGM Maintenance Free Battery

- Flooded Maintenance Free Battery

- 1-1/4″ or 1-1/2″ Slip x Slip Check Valve

- 1-1/2″ Inline Check Valve

- 1-1/4″ Z-Rail® Disconnect System

- 2″ Z-Rail® Disconnect System

- View All

- 912 Simplex Sewage Package System with an M264

- 912 Simplex Sewage Package System with an BN264

- 912 Simplex Sewage Package System with an M264

- 912 Simplex Sewage Package System with an M264

- 912 Simplex Sewage Package System with an BN264

- 912 Simplex Sewage Package System with an BN264

- 912 Simplex Sewage Package System with an M266

- 912 Simplex Sewage Package System with an BN266

- View All

- Model 803 Grinder Pump

- Model 805 Grinder Pump

- Model 807 Grinder Pump

- Model 818 Grinder Pump

- Model 803 Grinder Pump

- Model 805 Grinder Pump

- Model 807 Grinder Pump

- Model 810 Progressing Cavity Grinder Pump

- Model 815 Progressing Cavity Grinder Pump

- Model 820 Grinder Pump

- Model 820 Grinder Pump with Switch

- Model 840 Grinder Pump

- View All

- Aquanot® Key 507

- Aquanot® Spin 508

- Aquanot® Fit 508

- Aquanot® Spin 508 ProPak with M53

- Aquanot® Fit 508 ProPak with M53

- Aquanot® Fit 508 ProPak with M63

- Aquanot® Spin 508 ProPak with M98

- Aquanot® Fit 508 ProPak with M98

- 540 FLEX®Water Powered Backup

- AGM Maintenance Free Battery

- Flooded Maintenance Free Battery

- View All

- Simplex Pivot Control Panel, 7-15 Amps

- Simplex Pivot Control Panel, 15-20 Amps

- Duplex Pivot Control Panel, 0-7 Amps

- Duplex Pivot Control Panel, 0-20 Amps

- Duplex Pivot Control Panel, 7-15 Amps

- Duplex Pivot Control Panel, 15-20 Amps

- Simplex Pivot Pro Control Panel, 2.5-4.0 Amps

- Duplex Pivot Pro Control Panel, 2.5-4.0 Amps

- Duplex Pivot Pro Control Panel, 4.0-6.3 Amps

- Duplex Pivot Pro Control Panel, 6-10 Amps

- Duplex Pivot Pro Control Panel, 7-15 Amps

- Duplex Pivot Pro Control Panel, 9-14 Amps

- View All

- 15′ 13 Amp Single Piggyback Variable Level Float Switch

- 10′ 13 Amp Single Piggyback Variable Level Float Switch

- 15′ 15 Amp Single Piggyback Variable Level Float Switch

- 15′ Double Piggyback Variable Level Float Switch

- 15′ Variable Level Control Switch

- 20′ Variable Level Control Switch

- 25′ Variable Level Control Switch

- 25′ Narrow Angle Level Control Switch

- 50′ Narrow Angle Level Control Switch

- Oil Smart® Pump Switch

- View All

- 1-1/4″ or 1-1/2″ Slip x Slip Check Valve

- 1-1/2″ Inline Check Valve

- 1-1/2″ Quiet Check Valve

- 1-1/2″ Clear Quiet Check Valve

- 1-1/2″ Tri-Check® Valve

- 1-1/2″ Combo Check Valve

- 1-1/2″ Compression Unicheck

- 2″ Tri-Check® Valve

- 2″ Quiet Check Valve

- 2″ Unicheck Cast Iron Check Valve

- 2″ Quiet Check Valve

- 2″ Cast Iron Full-Flow Unicheck

- View All

- Standard APak® Outdoor Alarm System With Mechanical Float

- Standard APAK® Indoor Alarm With Reed Sensor

- Standard APAK® Indoor Alarm With Mechanical Float

- Z Control® APAK® Indoor Alarm With Reed Sensor

- Z Control® APAK® Indoor Alarm With Mechanical Float

- Flood Alert® High Water Alarm

- High Water Qwik Alarm™

- View All

- PSF Extension for 18×30 Basin (12″ Tall)

- PSF Extension for 18×30 Basin (6″ Tall)

- Fiberglass Extension for 18×30 Basin (12″ Tall)

- Fiberglass Extension for 18×30 Dia Basin (6″ Tall)

- 8″ Extension for Indoor 24×24 Sewage Ejector System

- 18″ Riser for Outdoor 24×24 Sewage Ejector System

- 18″ x 30″ Polyethylene Basin

- 18″ x 22″ Polyethylene Basin

- 24″ x 48″ Fiberglass Basin

- 18″ Sump Basin Cover

- Outdoor Tank Vent

- 18″ x 30″ Polyethylene Basin with Steel Cover

- View All

Color 1

Color 2

Color 3

Color 4

Color 5